Industrial Engineering

Production and Manufacturing System Design

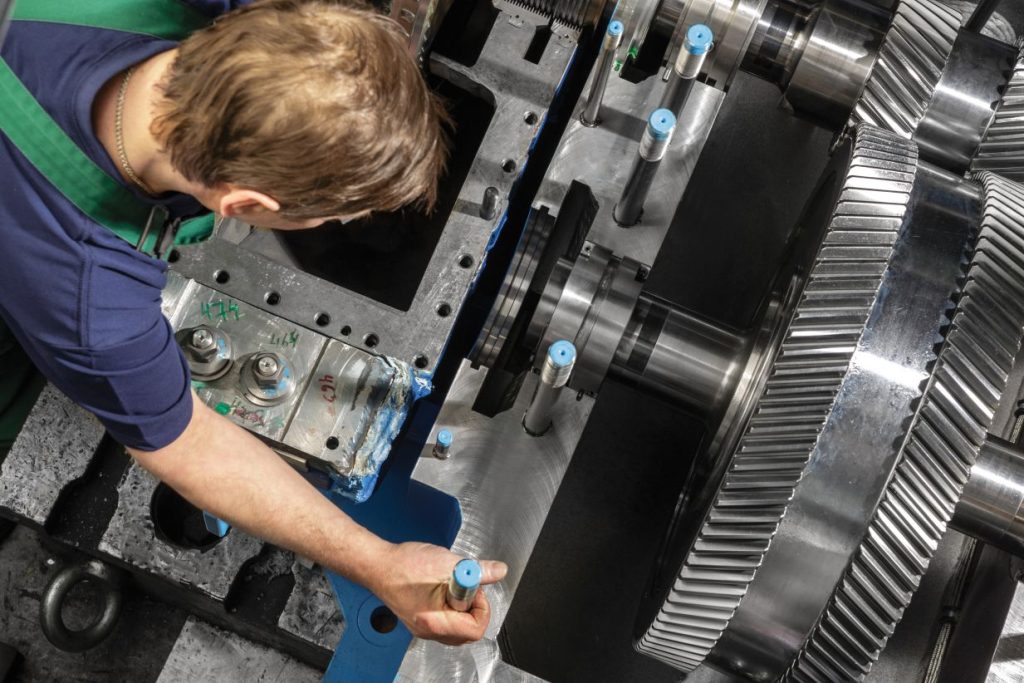

Texas Gears and Engineering optimizes production processes for increased efficiency in various industries, including mineral processing, energy, and manufacturing. Leveraging our expertise and innovative technologies, we tackle industry-specific challenges to enhance operational efficiency and equipment performance. Our commitment to excellence makes us a trusted partner for companies aiming to boost productivity and competitiveness in the fast-paced industrial sector.

Operations Research Consulting

Texas Gears and Engineering provides analytical services to optimize operations, including resource allocation and decision analysis. Using advanced tools, we uncover insights for improvement, enhance productivity, mitigate risks, and maximize returns. Our focus on results and continuous improvement makes us a trusted partner for businesses aiming for growth and potential maximization.

Risk Analysis

We use probabilistic models for comprehensive risk assessment and strategic planning. By identifying and mitigating potential risks in dynamic business environments, we quantify the likelihood and impact of risks, and guide clients towards proactive risk management strategies. Our focus on anticipating risks enables businesses to confidently navigate uncertainties, promoting resilience and sustainable growth.

Industrial Simulation

Texas Gears and Engineering offers simulation modeling services to replicate real-world operations, predict outcomes, and optimize performance. These models serve as decision-making tools, allowing clients to explore scenarios and strategies before implementation. Clients can identify bottlenecks, optimize resources, and enhance efficiency, driving cost savings and performance improvement. This ability to simulate various scenarios provides strategic insights for competitive advantage in today’s dynamic market.

Lean Manufacturing Implementation

We assist organizations in adopting lean principles to reduce waste and improve efficiency. Lean manufacturing maximizes value and minimizes waste, enhancing efficiency, quality, and profitability. It streamlines workflows, reduces lead times and costs, optimizes resources, and responds quickly to market trends. Emphasizing continuous improvement and employee empowerment, it fosters innovation and accountability. Practices like Kaizen engage employees in operational excellence, boosting satisfaction and retention. Lean manufacturing provides a holistic approach to efficiency and performance, enabling sustainable success in a competitive market.

Engineering Management Consulting

Texas Gears and Engineering provides comprehensive management strategies to enhance project execution, team performance, and organizational efficiency. Our experienced team crafts tailored solutions that drive success from start to finish, leveraging industry–best practices.

Our approach is centered on ensuring project success through careful planning, efficient execution, and continuous monitoring. We collaborate with clients to understand their unique needs and develop customized management strategies for each project and organization.

Throughout the project lifecycle, our team remains actively engaged, overseeing every aspect of the process from start to finish. Regular check-ups at specific intervals allow us to track progress, identify potential roadblocks, and make timely adjustments as needed. By maintaining open lines of communication and fostering transparency, we ensure that our clients are informed and empowered to make informed decisions at every stage of the project.

Our team stays engaged throughout the project, overseeing all aspects and making timely adjustments. We use regular check-ups to track progress and identify potential issues. By fostering transparency and communication, we empower clients to make informed decisions at each stage.

Texas Gears and Engineering provides proactive management strategies and support, enabling clients to achieve optimal outcomes, maximize team performance, and drive efficiency. Our commitment to excellence and successful track record makes us trusted partners for operational excellence and sustainable growth.

Logistics and Network Design

We customize and optimize logistics networks for maximum efficiency in supply chains. We optimize transportation routes, redesign distribution centers, and implement advanced inventory systems to enhance goods flow. By integrating cutting-edge technology and best practices, we help clients minimize costs, reduce lead times, and improve supply chain performance, enabling businesses to stay agile and competitive.

Quality Control and Reliability Services

As an ISO 9001:2015 certified organization, Texas Gears and Engineering implements rigorous quality control and reliability engineering to ensure product consistency and dependability. We uphold high quality standards through meticulous monitoring, testing, and analysis throughout the product lifecycle. Continual process refinement and innovation help us exceed customer expectations and deliver reliable, consistent, and durable products.

Computer Integrated Manufacturing Systems

Implementing Computer Integrated Manufacturing Systems (CIMS) with Texas Gears and Engineering marks a transformative step towards enhancing your manufacturing processes. By seamlessly integrating computer technology into every facet of your operations, CIMS revolutionizes how you design, produce, and manage your products. With CIMS, we can streamline your production workflows, automate repetitive tasks, and optimize resource utilization, leading to significant improvements in efficiency and productivity. Real-time data collection and analysis capabilities offered by CIMS enable you to monitor key performance indicators, identify areas for improvement, and make informed decisions on the fly.

Moreover, CIMS facilitates seamless communication and collaboration across departments, ensuring that every aspect of your manufacturing process operates in harmony. With enhanced precision, accuracy, and flexibility, CIMS empowers you to meet evolving customer demands, deliver higher-quality products, and maintain a competitive edge in today’s fast-paced market. In essence, integrating Computer Integrated Manufacturing Systems with Texas Gears and Engineering elevates your process to new heights, driving innovation, efficiency, and success across the board.

Human Factors and Ergonomics Analysis

Texas Gears and Engineering specializes in evaluating and designing environments and interfaces to optimize human interaction, safety, and comfort. We create tailored solutions that enhance user experience and well-being, design user-friendly interfaces, and optimize workspaces. By integrating ergonomic principles and safety protocols, we promote productivity, safety, and satisfaction. Our designs prioritize human well-being and operational excellence.

Facilities Design and Material Handling Optimization

We plan and optimize facility layouts and material handling systems for efficiency and safety. We use advanced modeling software and engineering expertise to optimize layouts and workflows, strategically position equipment, and streamline material flow. Texas Gears and Engineering prioritizes safety by integrating ergonomic design principles and safety protocols, ensuring facilities are efficient, productive, and safe.

Inventory Control and Management

Texas Gears and Engineering develops robust inventory management strategies to minimize costs and ensure product availability. We use advanced analytics and forecasting to predict demand, maintain optimal inventory levels, and avoid overstocking. We design efficient replenishment systems, use just-in-time principles, and implement tracking technologies to improve visibility and accuracy. Our expertise in inventory management helps clients save costs, maximize efficiency, and confidently meet customer demands.