Process Optimization

Industrial Simulation

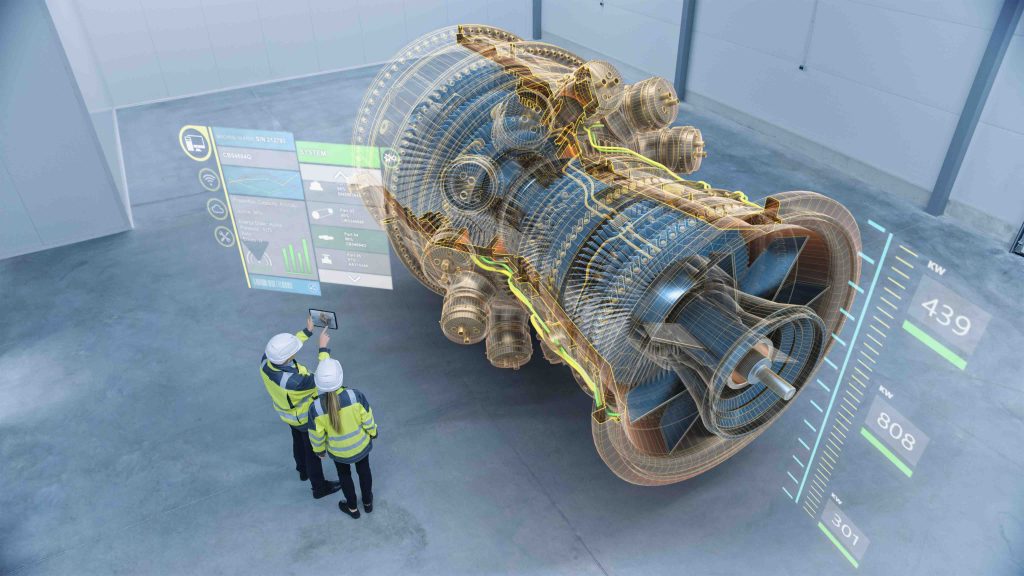

Offer simulation modeling to mimic real-world operations, predict outcomes, and optimize system performance. Texas Gears and Engineering stands at the forefront of innovation by offering advanced simulation modeling services, which replicate real-world operations with unparalleled accuracy. Through sophisticated modeling techniques, our team creates virtual environments that mimic the complexities of our client’s systems, enabling us to predict outcomes and optimize performance with precision. These simulations serve as invaluable decision-making tools, allowing businesses to explore various scenarios and strategies in a risk-free environment before implementation. By leveraging simulation modeling, our clients can identify bottlenecks, optimize resource allocation, and enhance operational efficiency, ultimately driving cost savings and improving overall system performance. With the ability to simulate a wide range of scenarios, from production line optimizations to supply chain logistics, Texas Gears, and Engineering provides its clients with the strategic insights needed to stay ahead of the competition and thrive in today’s dynamic marketplace.

Lean Manufacturing Implementation

Assist organizations in adopting lean principles to reduce waste and improve process efficiency. Lean manufacturing also offers a multitude of benefits for businesses across various industries, revolutionizing traditional production processes and driving sustainable growth. At its core, lean manufacturing focuses on maximizing value while minimizing waste, resulting in enhanced efficiency, improved quality, and increased profitability. One of the primary benefits of lean manufacturing is its ability to streamline workflows and eliminate non-value-added activities, leading to significant reductions in lead times and production costs. By optimizing resource utilization and minimizing inventory levels, lean practices help businesses respond more quickly to changing customer demands and market trends, fostering greater agility and flexibility. Additionally, lean manufacturing emphasizes continuous improvement and employee empowerment, creating a culture of innovation and accountability within the organization. Through practices such as Kaizen and visual management, businesses can engage employees at all levels in the pursuit of operational excellence, resulting in higher levels of employee satisfaction and retention. Overall, lean manufacturing offers a holistic approach to operational efficiency and performance optimization, enabling businesses to achieve sustainable success in today’s competitive marketplace.